Why do Long Arm Quilters need extra backing for a quilt??

I get asked this question a lot. The answer is simple if you know how the different quilting options work. When you hand quilt or quilt it on your domestic machine your don’t need as much extra backing. So why do you need 6-8 inches or more when it’s quilted on a Long arm? Let me show you…

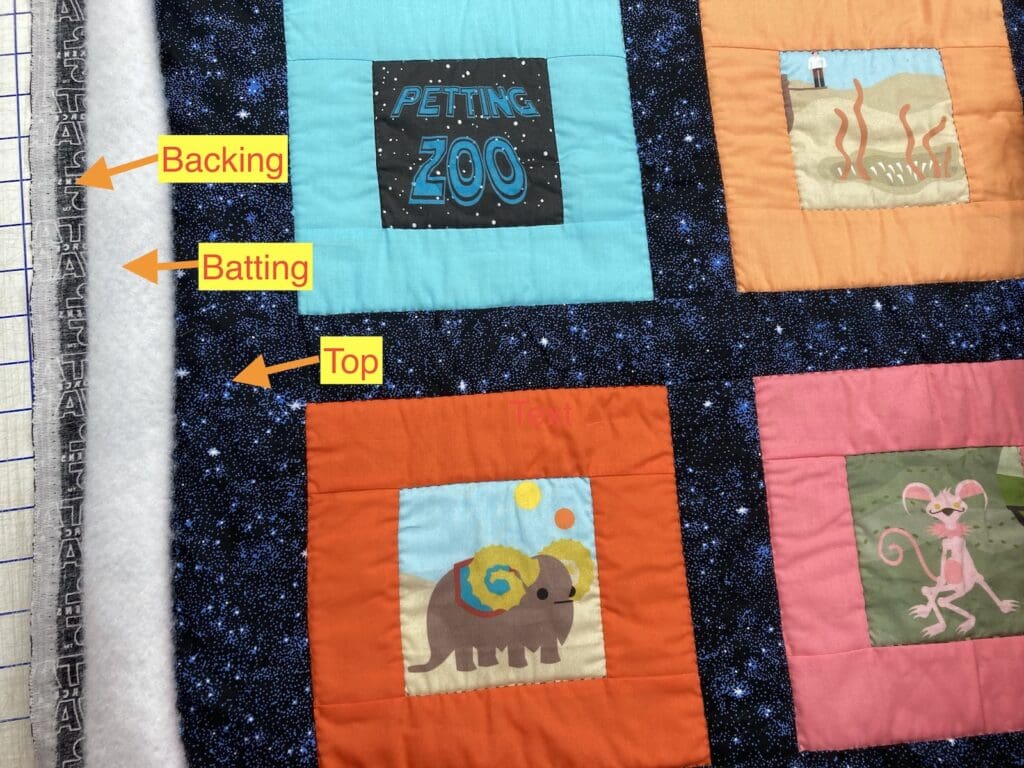

The difference is the way we put our quilt sandwiches together. The first two methods, you put the top, batting, and backing together all at one time.Then you spay, pin or baste it and you’re ready to go. Like a big sandwich with the batting as the middle. A couple of extra inches around the top is enough for any shifting in the materials as you quilt.

When you use a Long Arm machine, you make the sandwich as you go. Today I loaded this beautiful quilt made by one of my talented clients.

I started with the backing, loading it on the two poles upside down. Rolling most of it on the pole at the front of the machine which make the pole on the back the top of the quilt. You add it to the poles using fabric panels called leaders. You can attach the backing by pinning it, using a zipper system, or as I do with a system called Red Snappers that clamp the fabric between a rod and the clamp. This takes about 1 1/2inches on the top and bottom and you need a little extra room for your machine to move without hitting them. This is were the extra fabric comes into play.

Next I load the batting. It just lays on the backing, this will be stitched to the backing with a straight line to give you a mark to line the quilt top too.

There are 2 ways to load the top. The first method is to roll it up on the front pole above the backing (this is the pole on my machine with the blue painters tape.) I prefer the floating method where you let it hang down the front and adjust it as you go. I feel I have more control with how it gets quilted this way. Both method have you attach the top of the quilt to the batting and backing to secure it.

Now that we have it secure at the top and bottom we need to secure the sides so they don’t get pull to the center and get the quilt all out of square. We use clamps to do this. And here is where those extra inches are needed. We need it secure and also out of the way of the machine stitching to the edge of the quilt. My machine needs at least 3 inches, but 4 is better so that the machine Can move around without hitting the clamps. I made a little video of the machine in action. My Handi Quilter Avante has Pro Stitcher which is a computerized stitching program that does the stitching once I set it up. Hope you enjoy it and get a glimpse into how a Long Arm Machine runs!